Food and Beverage Processors (General)

A guide to inspection frequencies

properties.trackTitle

properties.trackSubtitle

Employers have a duty of care to ensure the health, safety and welfare of their employees. Periodic inspections and/or thorough examinations on their plant and equipment form part of this vital duty, whilst also ensuring employer conformity to applicable health and safety legislation.

Manufacturers rely on a wide range of equipment and process plant for their day-to-day operations, with various work processes occurring depending on the type of business operation.

Plant and equipment within the workplace needs to be examined and properly maintained to ensure it is safe to operate, and that it complies with applicable health and safety legislation; requiring statutory examinations at specific intervals, which exist outside normal equipment maintenance and servicing procedures.

Regular inspections may also serve as a good preventative maintenance programme to ensure the integrity of plant and equipment; helping to minimise machinery breakdowns and production downtime.

Inspection frequencies

Different types and categories of equipment have varying inspection frequencies according to applicable health and safety legislation.

Typical equipment and installations found within food and beverage processing premises are listed below, together with the applicable legislation.

UK

Lifting

| Applicable legislation (1) | Typical equipment | Inspection/thorough examination frequency (months) |

|---|---|---|

| Lifting Operations and Lifting Equipment Regulations 1998 | Forklift truck (goods only) | 12 |

| Lifting machine attachments (forklift truck attachment) | 12 | |

| Swing jib crane | 12 | |

| Goods/service lift | 12 | |

| Mobile elevating work platform (MEWP) | 6 | |

| Order picker (lifting persons/lifting goods) | 6/12 | |

| Mobile crane (goods only) | 12 | |

| Overhead travelling crane | 12 | |

| Runway track | 12 | |

| Vehicle tailboard lift | 6-12 | |

| Fall protection equipment (harness with lanyard) | 6 | |

| Lifting accessories (removable eyebolt) | 6 | |

| Lifting assembly (accessories permanently attached to lifting equipment) | 12 | |

| Provision and Use of Work Equipment Regulations 1998 | Pallet truck | 12 |

| Conveyor system | 12 |

Boiler/Pressure

| Applicable legislation (1) | Typical equipment | Inspection/thorough examination frequency (months) (2) |

|---|---|---|

| Pressure System Safety Regulations 2000 | Air receiver (>250 bar/litres) | 26 |

| Air/oil receiver | 72 | |

| Provision and Use of Work Equipment Regulations 1998 | Hot water boiler (<110ºC) (3) | 12 |

| Expansion vessel (used for hot water systems) (3) | 12 | |

| Refrigeration and air conditioning systems (<25 kW) (3) | 12 |

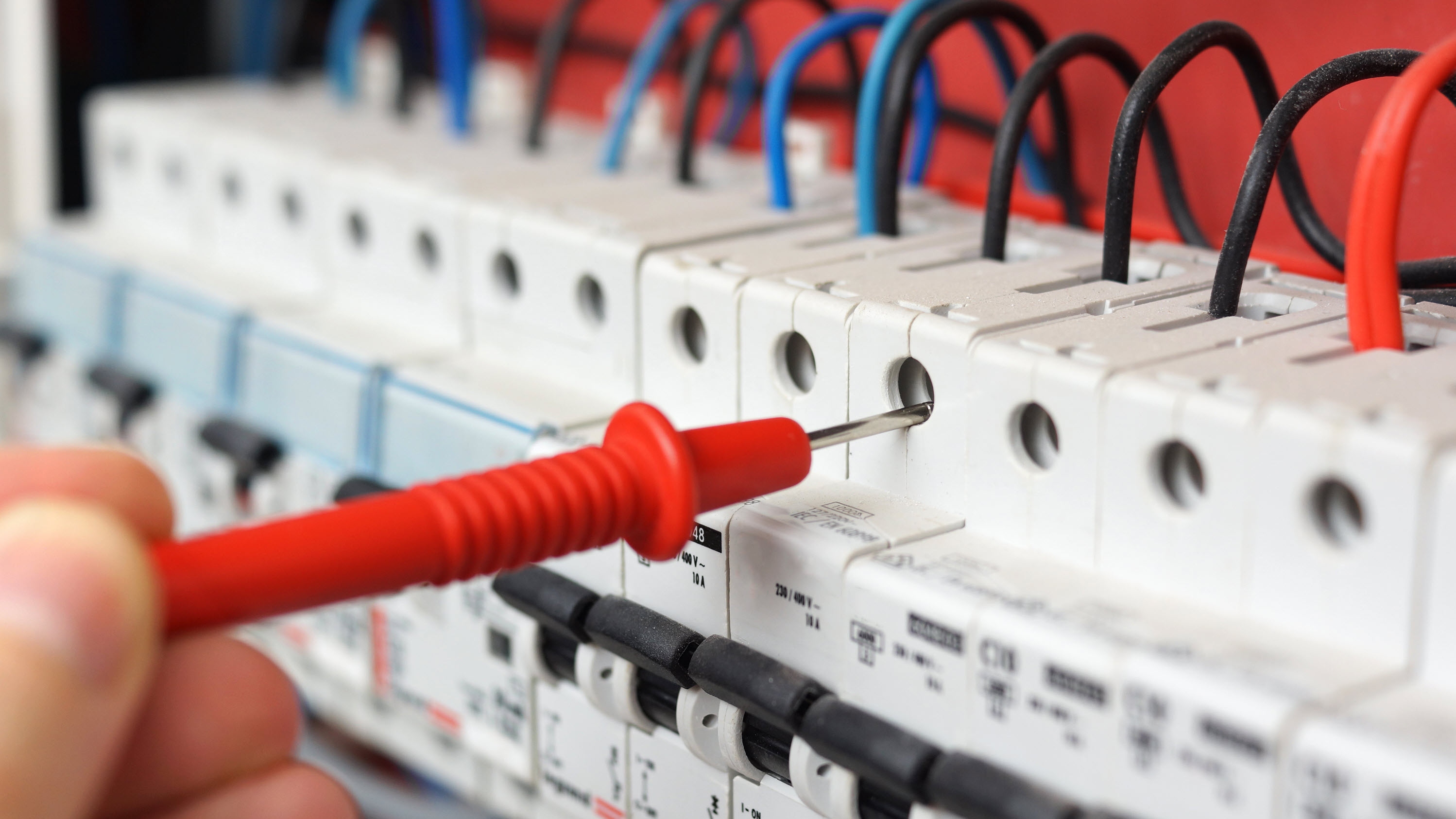

Electrical/Mechanical Plant

| Applicable legislation (1) | Typical equipment | Inspection/thorough examination frequency (months) |

|---|---|---|

| Provision and Use of Work Equipment Regulations 1998 | Alternator | 12 |

Local Exhaust Ventilation

| Applicable legislation (1) | Typical equipment | Inspection/thorough examination frequency (months) |

|---|---|---|

| The Control of Substances Hazardous to Health Regulations 2002 | Fume extraction | 14 |

| Dust extraction (non-metallic) | 14 |

Electrical Systems

| Applicable legislation (1) | Typical equipment | Inspection/thorough examination frequency (months) (2) |

|---|---|---|

| Electricity at Work Regulations 1989 | Low voltage electrical installations | 36 |

| Portable appliances | 12 |

Ireland

Lifting

| Applicable legislation | Typical equipment | Inspection/thorough examination frequency (months) |

|---|---|---|

| S.I. No. 299 of 2007: Safety, Health and Welfare at Work (General Application) Regulations 2007 | Forklift truck (goods only) | 12 |

| Lifting machine attachments (forklift truck attachment) | 12 | |

| Swing jib crane | 12 | |

| Goods/service lift | 6 | |

| Mobile elevating work platform (MEWP) | 6 | |

| Order picker (lifting persons/lifting goods) | 6/12 | |

| Mobile crane (goods only) | 12 | |

| Overhead travelling crane | 12 | |

| Runway track | 12 | |

| Vehicle tailboard lift | 12 | |

| Fall protection equipment (harness with lanyard) | 6 | |

| Lifting accessories (removable eyebolt) | 6 | |

| Lifting assembly (accessories permanently attached to lifting equipment) | 12 | |

| S.I. No. 299 of 2007 (Regulation 30): Safety, Health and Welfare at Work (General Application) Regulations 2007 | Pallet truck | 12 |

| Conveyor system | 12 |

Boiler/Pressure

| Applicable legislation | Typical equipment | Inspection/thorough examination frequency (months) |

|---|---|---|

| S.I. No. 445 of 2012: Safety, Health and Welfare at Work (General Application) (Amendment) Regulations 2012 | Air receiver (>250 bar/litres) | 26 |

| Air/oil receiver | 72 | |

| S.I. No. 299 of 2007 (Regulation 30): Safety, Health and Welfare at Work (General Application) Regulations 2007 | Hot water boiler (<110ºC) | 12 |

| Expansion vessel (used for hot water systems) | 12 | |

| Refrigeration and air conditioning systems (<25 kW) | 12 |

Electrical/Mechanical Plant

| Applicable legislation | Typical equipment | Inspection/thorough examination frequency (months) |

|---|---|---|

| S.I. No. 299 of 2007 (Regulation 30): Safety, Health and Welfare at Work (General Application) Regulations 2007 | Alternator | 12 |

Local Exhaust Ventilation

| Applicable legislation | Typical equipment | Inspection/thorough examination frequency (months) (1) |

|---|---|---|

| Health & Safety Authority: Local Exhaust Ventilation (LEV) Guidance document | Fume extraction | 12 |

| Dust extraction (non-metallic) | 12 |

Electrical Systems

| Applicable legislation | Typical equipment | Inspection/thorough examination frequency (months) |

|---|---|---|

| S.I. No. 299 of 2007 (Part 3): Safety, Health and Welfare at Work (General Application) Regulations 2007 | Low voltage electrical installations | 36 - Industrial (1) |

| 60 - Commercial (1) | ||

| Portable appliances | 3-60 (2) |

How HSB can help

HSB Inspection Services: Our network of competent, multi-skilled Engineer Surveyors help customers throughout the UK and Ireland to maintain workplace equipment safety, optimise the efficiency of plant and equipment, and comply with applicable health and safety legislation; covering boiler/pressure, lifting, electrical/mechanical, dust and fume extraction, power press equipment, and fixed wiring installations.

HSB Risk Management Solutions: We can help businesses to reduce risks, costs, and deliver compliance via improved analysis of their equipment and health and safety practices. Consisting of three services, each service is further split into modules, allowing customers to build them to fit their business.

Plant guide: Diagrams

View detailed diagrams of typical plant and equipment used across various industries, together with applicable legislation for each item.