5 ways 3D printing can add risk

properties.trackTitle

properties.trackSubtitle

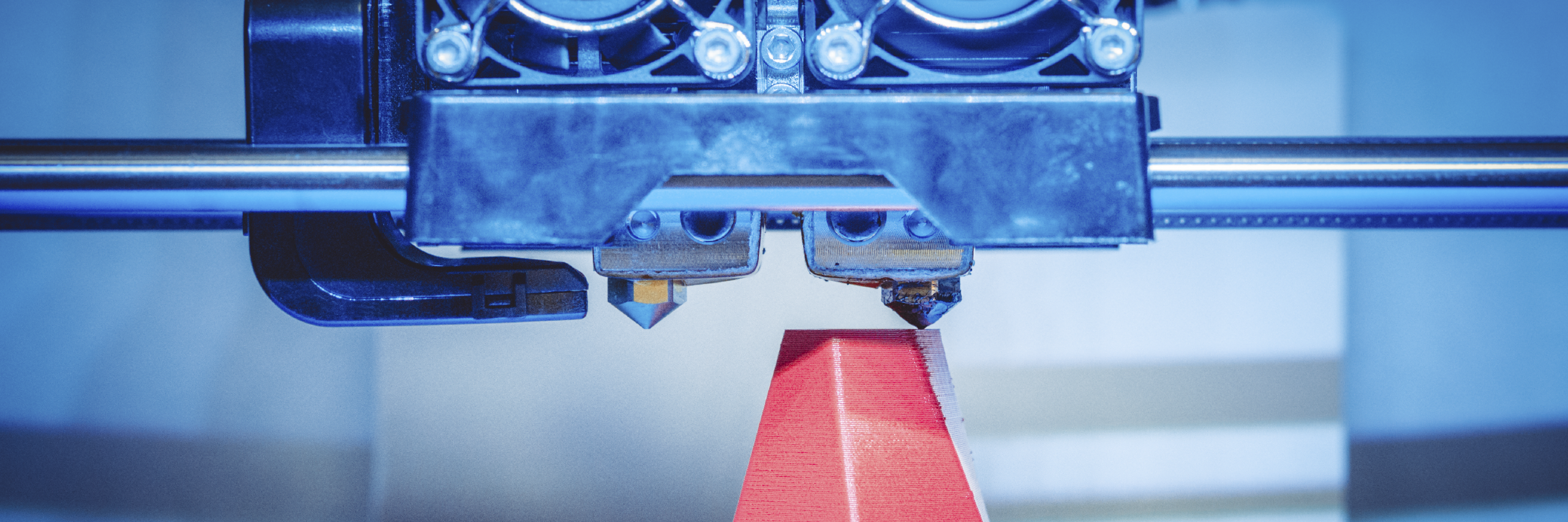

A part flies off a production line, causing damage and downtime to the operation. While the machinery was originally imported from Europe to North America, with changing technology, the part is now redundant and its replacement near impossible. An obvious and now more common solution is to 3D-print the object, reducing downtime, lost revenues and extra expense.

However, as with all emerging technologies, 3D printing presents new challenges to the insurance industry.

Here are 5 ways 3D printing can add risk:

1. Some 3D printing processes are hazardous

2. 3D printed parts can fail

3. 3D printers can break down and cause widespread electrical damage

3D printers themselves are ‘insured objects’ and subject to equipment breakdown perils.

A recent claim involved an obsolete print head, which caused an overvoltage condition, damaging 62 of the insured’s electrical outlets. This caused damage, considerable downtime and a complete loss of the 3D project.

4. Liability shifts if there is an accident

5. Traditional testing and inspection methods may not apply to 3D printed parts

HSB has embraced industrial 3D printing and is actively involved in ASME’s new Special Committee on Use of Additive Manufacturing for Pressure Retaining Equipment, whose mission is to develop technical guidelines addressing materials, design, fabrication, examination, inspecting and testing.